The aim of railway network management is to optimize the asset life cycle, while ensuring sustainability and ongoing levels of high infrastructure availability, reliability, quality and safety.

The asset management model is based on knowledge of the state of infrastructure and the development of inspection capability.

IP focuses on suitable levels of human resources both with regard to quantity and competences, as well as on technologically advanced equipment from internal and external sources. Such equipment enables IP to have detailed knowledge on the state of infrastructure and provides us with the required diagnostics capacity so as to allow autonomy and response capacity.

More critical groups of assets are inspected with the frequency set out in a specific technical document. In the case of the railway network, this involves inspection of rail track geometry and ultrasonic analysis of the line and track direction changing devices, inspection of catenary geometry and special structures (bridges and tunnels).

Track geometry and ultrasonic line analysis

Main inspection activity of the line takes into consideration data obtained from inspection systems installed in an “EM120” vehicle. These data are complemented with other data obtained from light equipment, such as “KRAB” in situations where it is not possible or justified to use an “EM120”. Examples include inspection of narrow tracks or small isolated stretches of wide RFN tracks.

Two six-monthly inspection campaigns are conducted on the RFN in operation (general network campaigns), alternating with two other six-monthly campaigns, referred to as interim campaigns. Therefore, the RFN covered by these campaigns undergoes quarterly inspection.

Integrated into the main track inspection is an annual ultrasonic line analysis, running on a continuous basis with the use of a heavy vehicle, over a significant section of general wide track, which form the RFN in operation.

Line devices

The basis of Main Inspection to Track Devices consists of a detailed assessment of the general condition and state of the individual components. Periodical visits involve a series of dimensional checks to a vast variety of safety and functional parameters which, through comparison to admissible tolerances set out in a technical standard and good maintenance practices, allow safety of movement and the good operational performance of equipment to be ensured.

In addition to measuring instruments and more common tools, Main Inspection teams also have access to six items of equipment to measure gauge, scale and levels, a continuous track geometry inspection trolley, a portable transverse track profile laser measurement device and key parts.

The inspection route is covered annually and biannually, depending on the location and speed of the section in the RFN. This results in an average of 4,500 inspections per year.

Catenary

Main inspection of overhead contact lines takes into consideration continuous data obtained from inspection systems installed in an “EM120” vehicle. These data are complemented by other data obtained from light equipment such as a MEDCAT.

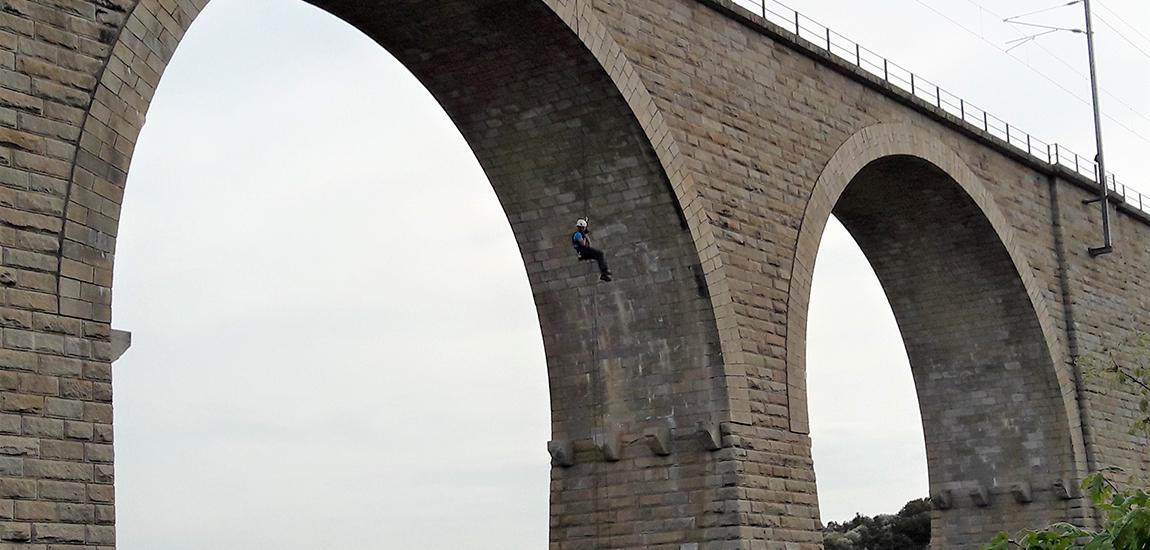

Special Structures

Currently, Infraestruturas de Portugal is considered to be the leading company in the field of engineering in Portugal and is also a benchmark internationally with regard to the Management and Inspection of Special Structures.

Main inspection frequency is based on special structure surveillance requirements. Depending on the frequency established, special structure inspection campaigns are then programmed and undertaken. Main inspections of the railway network take place on both main as well as branch lines.

Infraestruturas de Portugal has a brought together an established underwater inspection team, whose work includes observation dives, video recording and analysis of submersed anomalies, as well as topo-bathymetric studies to obtain riverbed levels and bank topography.

As a management support tool, IP has a Special Structure Management System, which is vital to detailed and ongoing knowledge of special structures and their structural condition. This Special Structure Management System incorporates a vast range of information gathered through periodic inspection activities, thus allowing early detection of intervention requirements and timely response in the reinforcement and rehabilitation of special structures.

This management methodology, together with the extensive experience and technical knowledge of our teams, has allowed ongoing improvement of the state of conservation of IP special structures to be achieved.