The aim of road network management is to optimize the asset life cycle, while ensuring sustainability and ongoing levels of high infrastructure availability, reliability, quality and safety.

The asset management model is based on knowledge of the state of infrastructure and the development of inspection capability.

IP focuses on suitable levels of human resources both with regard to quantity and competences, as well as on technologically advanced equipment from internal or external sources. Such equipment enables IP to have detailed knowledge on the state of infrastructure and provides us with the required diagnostics capacity so as to allow autonomy and response capacity.

More critical groups of assets are inspected with the frequency set out in a specific technical document, more specifically in the case of the road network, surfacing and special structures (bridges and tunnels).

Based on inspection requirements, asset management tools are developed which allow the impact of short-term economic decisions to be known, with respect to cost-performance-long-term risk, through:

(A) Methodologies to ascertain the state of assets, level of use they are subject to and current time in life cycle;

(B) Differentiated management models in accordance with the level of service, or availability for operation, for which performance must correspond;

(C) Identification of real intervention needs depending on required levels of service and also, the most suitable work to be carried out, time in the life cycle of the asset and the respective impact on its performance;

(D) Identification of risks associated with decisions to not carry out required work at the right time;

(E) Planning, based on a 20-year time frame, analysing cost scenarios gauging the corresponding risk and performance, as well as the resulting renovation liability.

The results obtained by current management systems at the company lead to preventive instead of reactive actions, where the latter are characterized as by greater risk, greater disruption to networks as well as higher investment.

Surfacing

Main inspection campaigns for surfacing are annual thus allowing the necessary indicators to be obtained for good conservation management and maintenance.

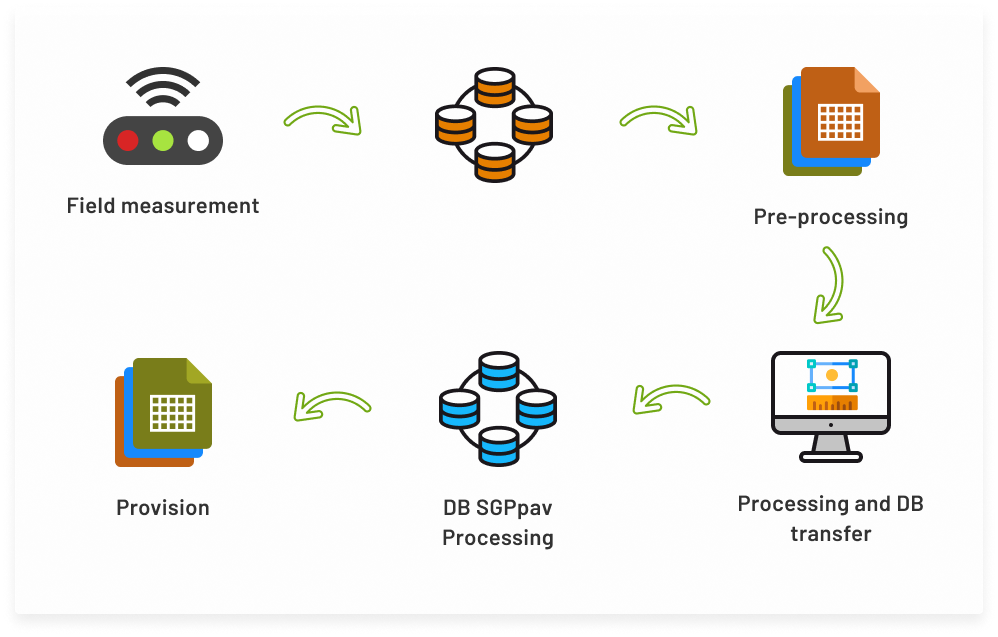

Data from the inspection process is used in a fully integrated manner with other information on management of surfaced assets, through the Surface Management System, which deals with the processing and provision of information:

Main steps in the processing and provision of data

Mechanical Inspection of Surfacing with a Laser Road Surface Tester

The Laser RST allows high-performance, continuous measurement providing a reading of longitudinal and transversal profiles of roads. Based on these profiles, it is possible to obtain a range of surface characteristics. This is a system consisting of 14 lasers to measure the distance to the surface, 2 accelerometers to discount vehicle motion when calculating parameters, 2 inclinometers and 1 gyroscope to obtain geometric parameters, and 1 distance measurement unit with GPS for information referencing.

The longitudinal profile of a road is obtained by measuring altimetric deviations of the surface in relation to an ideal profile. Based on this longitudinal profile, different indicators of surface regularity can be calculated, such as the International Roughness Index (IRI), as specified in the EN 13036-5 (2006) European standard. With the same measurement principle applied in longitudinal profile measurement, the RST also allows the transverse profile of surfacing to be determined. In addition to the longitudinal and transverse roughness of the surface, the RST also allows surface macrotexture (MPD) values to be obtained, together with a series of geometric parameters of the road such as longitudinal and transverse inclination and curvature radius.

At the same time as the mechanical gathering of data, the system also allows data to be obtained manually (via observation) through a keyboard of programmable keys to record events. The Laser RST equipment also includes two video cameras, one facing the driving direction and another facing opposite, which capture duly geo-referenced images.

Adherence (SKM measurement)

The SKM is an item of high-performance equipment which, through surface testing, allows the continuous Transverse Friction Coefficient (TFC) to be obtained. This equipment is produced and operated in accordance with the European Technical Specification CEN TS 15901-8 and the German TP Grift-StB (SKM).

Inspection with SKM provides a range of data to be obtained including the abovementioned Transverse Friction Coefficient (TFC), macro-texture (MPD), surface, air and water temperatures, referencing information such as the measurement distance and geographical coordinates, geometric data (transversal and longitudinal inclination and curvature radius) and photographs.

Special Structures

Currently, Infraestruturas de Portugal is the main company in the field of engineering in Portugal and is also a benchmark internationally with regard to the Management and Inspection of Special Structures.

Main inspection frequency is based on special structure surveillance requirements. Depending on the frequency established, special structure inspection campaigns are then programmed and undertaken.

As the National Road Network is extensive and spread over a large area, and where roads are often intertangled, inspection campaigns do not focus on specific roads but rather on criteria of proximity to and location in individual districts.

Infraestruturas de Portugal has a brought together an established underwater inspection team, whose work includes observation dives, video recording and analysis of submersed anomalies, as well as topo-bathymetric studies to obtain riverbed levels and bank topography.

As a management support tool, IP has a Special Structure Management System, which is vital to detailed and ongoing knowledge of special structures and their structural condition. This Special Structure Management System incorporates a vast range of information gathered through periodic inspection activities, thus allowing early detection of intervention requirements and timely response in the reinforcement and rehabilitation of special structures.

This management methodology, together with the extensive experience and technical knowledge of our teams, has allowed the ongoing improvement of the state of conservation of IP special structures to be achieved.